Expertise of Canard Soulard

From egg to table

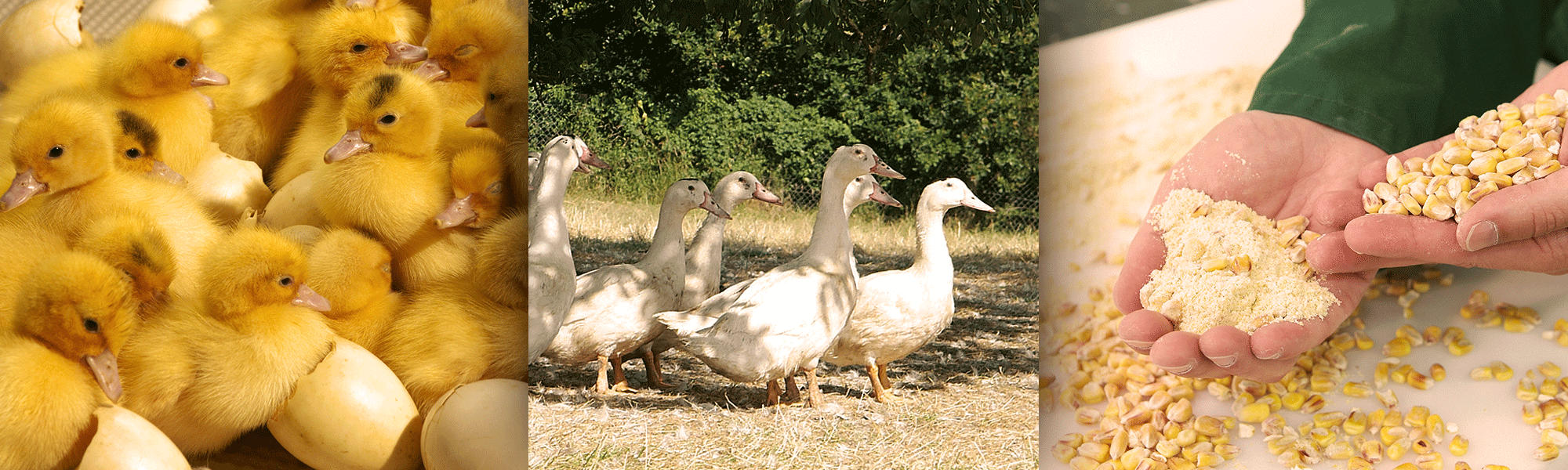

Hatching

In 1990, the company Ernest Soulard decided to increase its mastery of the production and quality of its products, by taking over a duckling hatchery in Remouillé.

From egg to duckling

Once laid, the eggs are gathered and sent to the hatchery. There, the eggs are placed in incubators that reproduce the heating provided by the female duck. After 15 days, the eggs are candled (passed in front of a light, in order to separate the fertilized from the unfertilized eggs). In the fifth week, the eggs are moved into hatchers. After they hatch, the ducklings are sent to our farmers in air conditioned vans.

Feeding

Controlling our ducks' feed means controlling the quality of the animals.

Diet is a decisive factor in raising a high-quality duck. With this in mind, Ernest Soulard decided to build its own feed plant in 1991. Our ducks are fed a 100% plant-based diet that guarantees the utmost quality. Our feed production business covers all of our farmers' needs.

Husbandry

At Ernest Soulard, we raise two breeds of ducks: Barbary ducks and mulard ducks.

Barbary ducks

Barbary ducks were a wild species from South America that was domesticated in the 16th century and imported by Christopher Columbus. They are sturdy and easy to raise. They stand out for their fairly lean, meaty flesh, whence their nickname of "lean ducks." Barbary duck can make a wide range of products, from whole duck to different cuts like the thigh, fillet or inner fillet.

Mulard ducks

Also known as "fatty ducks,"mulards are hybrids of male Barbary and female Pekin ducks. Their cross-breeding has yielded a rustic duck that can develop an excellent fatty liver for foie gras and meat that is particularly delicious.

Production

The company Ernest Soulard covers every aspect of processing, with an abattoir, cutting rooms, packaging shops and a freezer room.

Our building is located in L'Oie in Vendée and provides access to large spaces for plucking, drying and butchering.

Foie gras processing

To make itself completely independent in the creation of its foie gras preserves and semi-preserves, Ernest Soulard also has its own cannery.

After deveining the foie gras in the workshop, it is sent to the cannery. The livers are gently hand-seasoned, than packaged and cooked to order. The workshop is equipped with the necessary machinery and tools for making foie gras, with or without pieces and in a variety of containers, as requested.

To learn more, please visit our page on the history of foie gras.